- TOP

- Products

Products

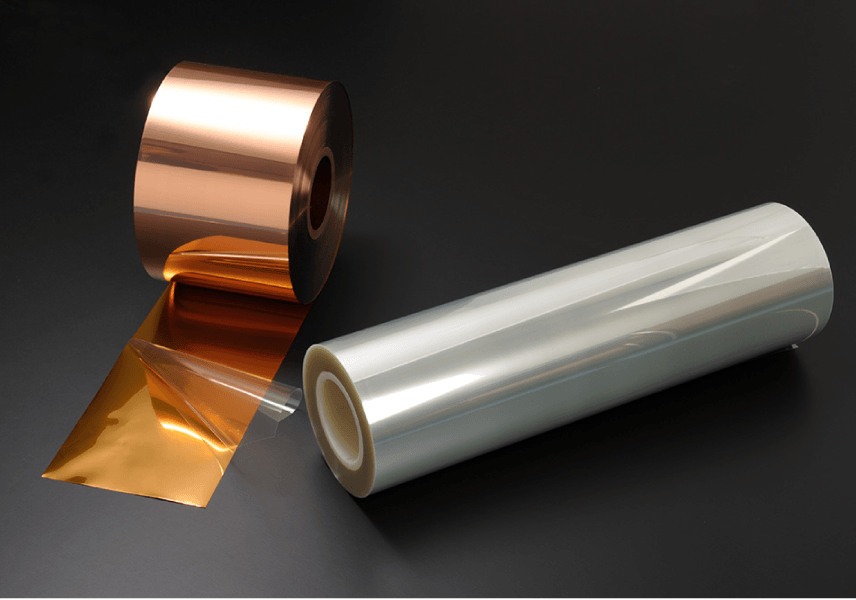

Materials for TAB/COF

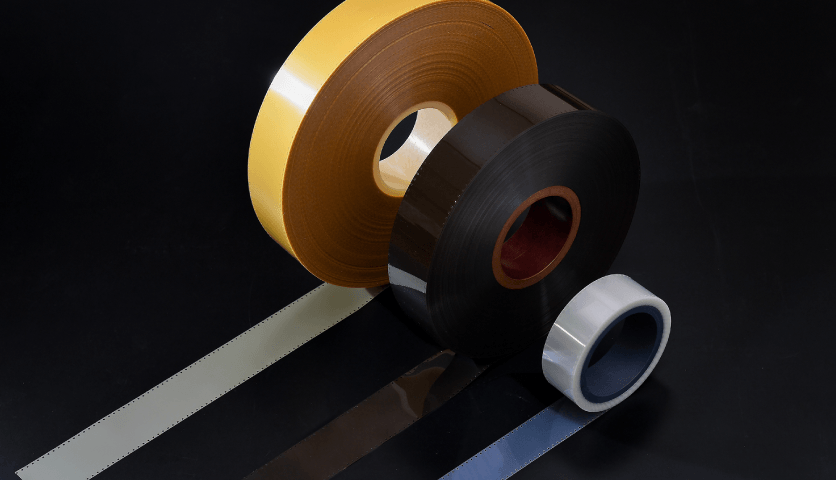

■ Lead tape (PEI, PI, PET)

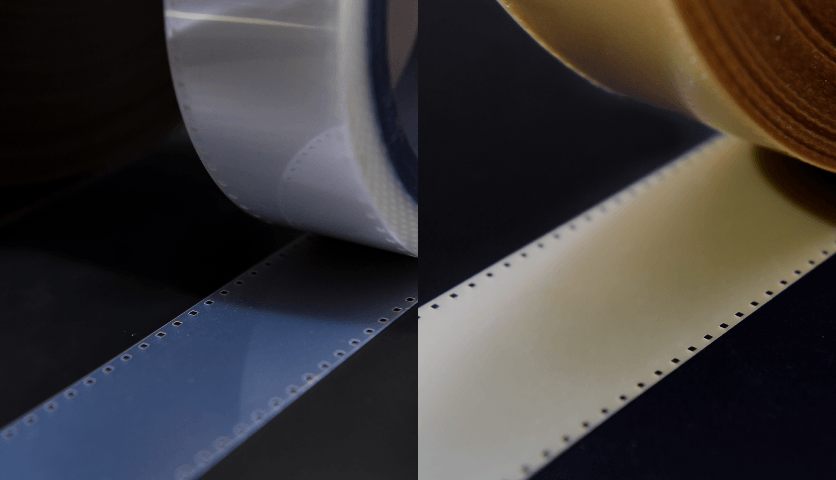

■ Lead tape (Photo enlargement)

List of main processing materials

| Products | Meterial | Thickness |

|---|---|---|

| Slit copper foil | ED copper | 9-70μm |

| RA copper | ||

| Laminate and slit products | CCL for COF with backup tape | According to CCL |

| Lead tape | PET film | 50-200μm |

| PEN film | ||

| PI film | ||

| PEI film |

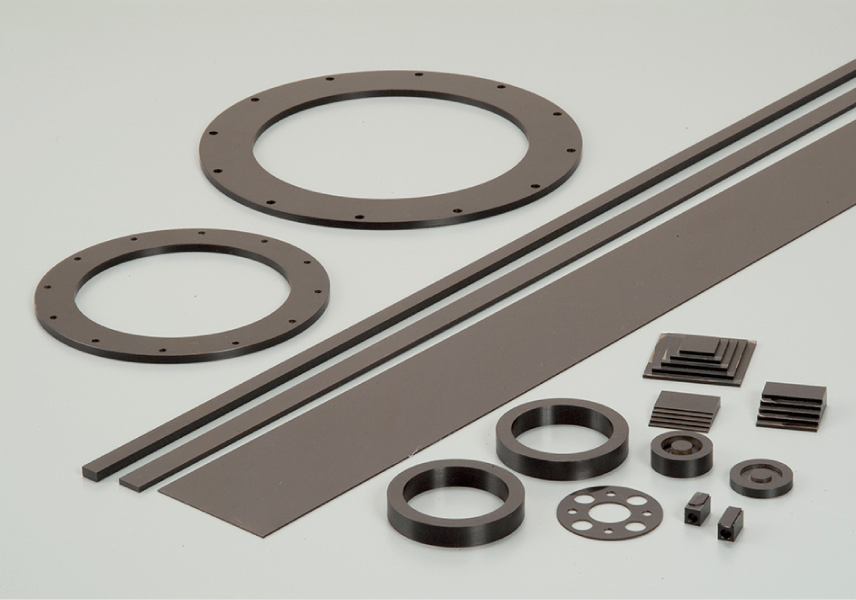

Polyimide laminate board

Polyimide laminate board which is manufactured by direct bonding of polyimide film which surface is activated by plasma treatment.

Polyimide laminate board exhibits excellent thermal resistance and mechanical properties.

| Maximum width | Maximum length | Maximum thickness |

|---|---|---|

| 480mm | 1,100mm | 10mm |

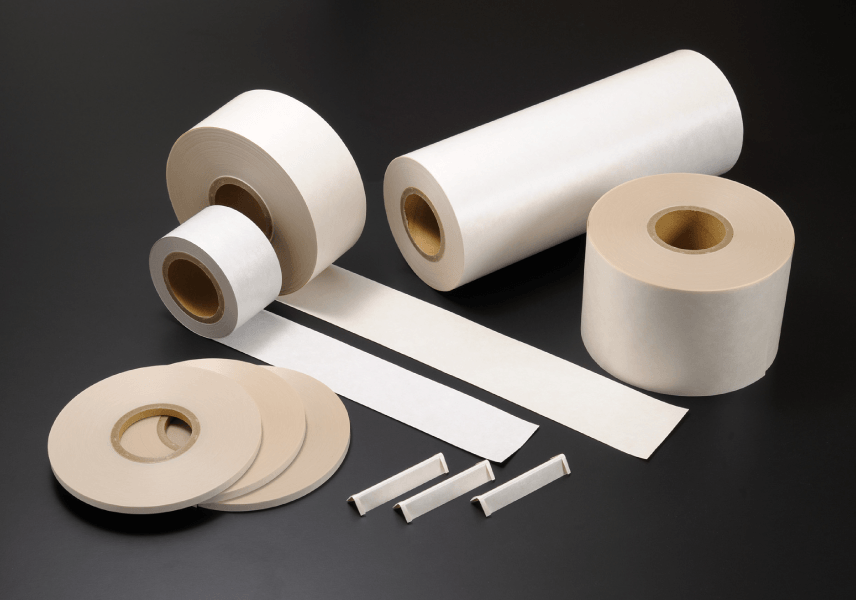

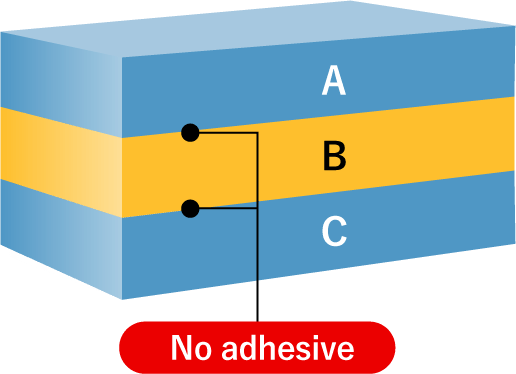

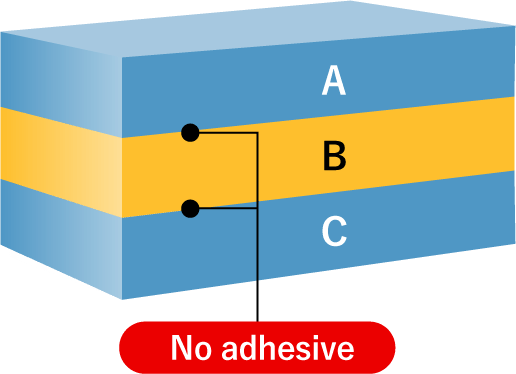

Non-adhesive multilayered insulating material

Namli® is a high performance multilayer electric insulating material which is manufactured by direct bonding of heat resistant insulating materials without adhesive.

Namli® has excellent heat resistance, oil resistance, hydrolysis resistance, and thermal conductivity required by motors for EV and HEV vehicles. The process does not emit volatile organic compounds (VOC), contributing to the reduction of global environmental impact.

NSN

- Composition

-

Material Thickness(mil) Thickness(μm) A NOMEX®(aramid paper) 2・3・5 50・75・125 B TORELINA®(PPS film) 2・3・4・4.5 50・75・100・115 C NOMEX®(aramid paper) 2・3・5 50・75・125 - Features

-

- 1)NOMEX® and PPS film “TORELINA®” are bonded without adhesive, and superior performances of NOMEX® and TORELINA® are fully utilized.

- 2)NSN is a heat resistant insulating material which exhibits excellent hydrolysis resistance and heat resistance.

- 3)NSN is suitable for the insulating materials of motors of EV/HEV and generators.

- 4)NSN shows good varnish impregnation performance as NOMEX® is used.

NKN

- Composition

-

Material Thickness(mil) Thickness(μm) A NOMEX®(aramid paper) 2・3・5 50・75・125 B KAPTON®(polyimide film) 1・2・3・5 25・50・75・125 C NOMEX®(aramid paper) 2・3・5 50・75・125 - Features

-

- 1)NKN is a super heat resistant insulating material which exhibits extremely high heat resistance.

- 2)Excellent property of KAPTON® is fully utilized.

- 3)NKN shows good varnish impregnation performance as NOMEX® is used.

*Nomex® and Kapton® are registered trademarks of DuPont de Nemours, Inc, and TORELINA® is a registered trademark of Toray Industries, Inc. Namli® is a registered trademark of Kawamura Sangyo Co., Ltd.

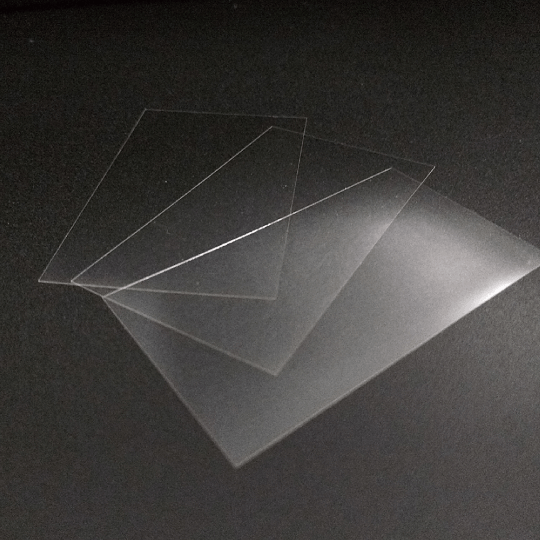

Solvent-soluble transparent polyimide “KPI-MX300F”

■ Powder

■ Varnish

(Polymer solution)

■ Usage example: film

Features

- KPI-MX300F is polyimide powder which is soluble in various solvents.

- KPI-MX300F gives transparent and heat resistant polyimide film.

Properties

| State | Item | Unit | Values(mm) | |

|---|---|---|---|---|

| Powder | Solvent | – | MEK,DMAc, γ-butyrolactone etc. |

|

| Properties of film (Film thickness: 50µm) |

Mechanical properties |

Tensile modulus | GPa | 3.9 |

| Elongation | % | 52 | ||

| Tensile strength | MPa | 150 | ||

| Thermal properties |

Coefficient of thermal expansion (CTE) |

ppm/K | 43 | |

| Glass transition temp (Tg) | ℃ | 354 | ||

| 5% weight reduction temp | ℃ | 530 | ||

| Optical properties |

Total Transmittance | % | 92 | |

| Yellow index (YI) | – | 1.3 | ||

| Haze | % | 0.6 | ||

*This data is reference values.

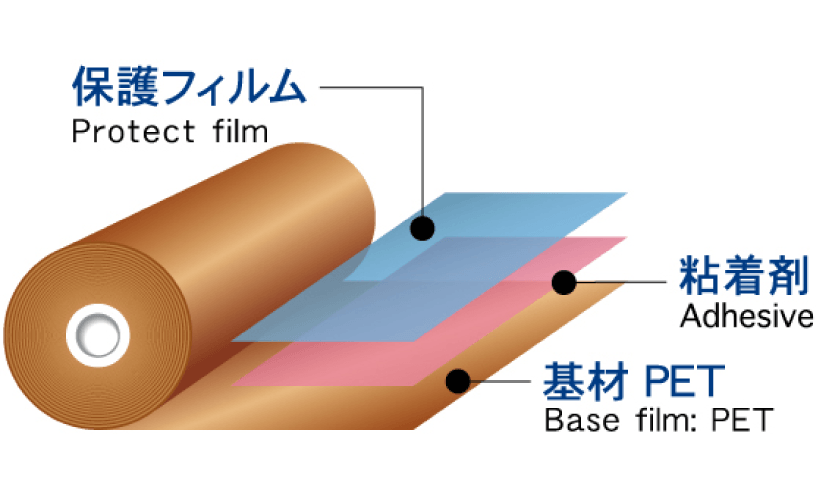

Backup tape

Backup tape which shows good removability after heat treatment at high temperature (150℃). This backup tape is suitable for support film of CCL for COF and protection film.

Composition

| Layer | Material | Standard thickness |

|---|---|---|

| Base film | PET | 50µm |

| Pressure sensitive adhesive (PSA) | Acrylic PSA | 8µm |

| Protection film | PET | 25µm |

Properties

| Heat treatment condition | Adhesion(N/cm) | Adhesive residue | ||

|---|---|---|---|---|

| Polyimide | Glass | Polyimide | Glass | |

| At room temp | 0.02 | 0.02 | none | none |

| 150℃×2 hours | 0.06 | – | none | – |

| 100℃×1hour | – | 0.03 | – | none |

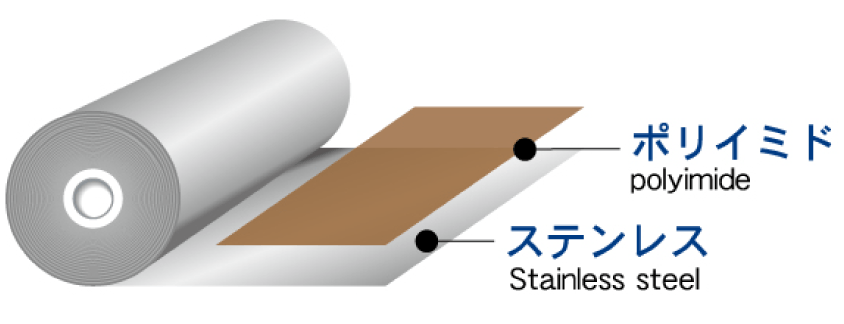

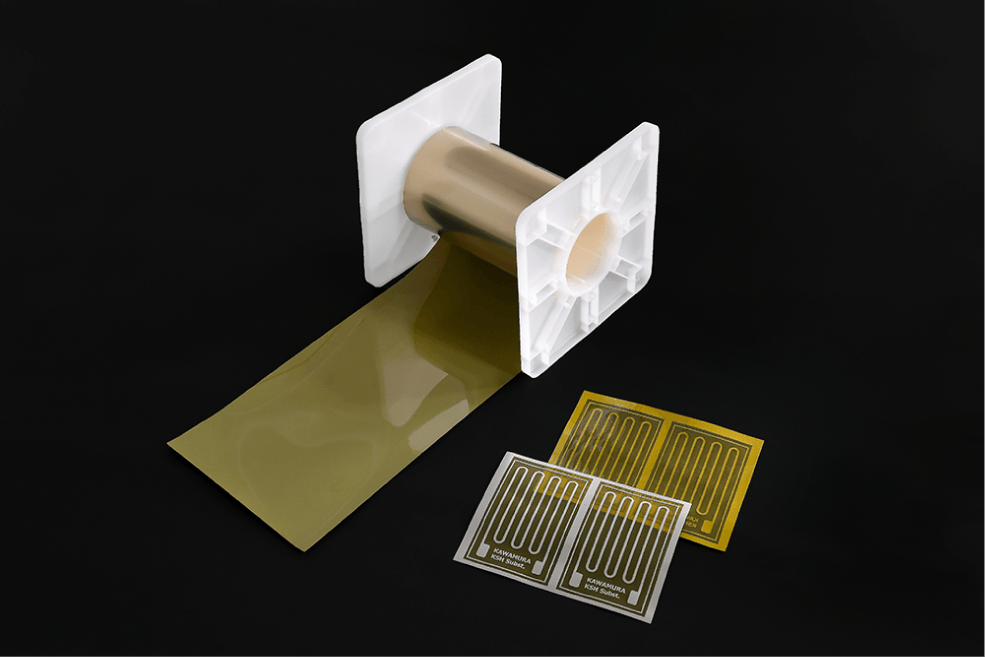

Stainless steel/polyimide material

High adhesion due to original polyimide design. Good flatness due to polyimide with low CTE.

Stainless steel/polyimide material is suitable for planar heating elements such as polyimide heater.

Composition

| Layer | Material | Standard thickness |

|---|---|---|

| Polyimide | Original Polyimide | 5-25µm(25µm) |

| Stainless | SUS304 | 15-50µm(30µm) |